The Central Reserve Grain Nest Lake Direct Subsidiary Warehouse, under the aegis of the Anhui Branch of the State Grain Reserves Corporation, plays a pivotal role in the storage and processing of grain. Encompassing four warehouse areas and a total storage capacity of 267,000 tons, the facility’s operational success hinges on maintaining a robust and efficient infrastructure. A crucial enhancement in this regard has been the recent incorporation of metal hoses and DIN rubber expansion joints into the warehouse’s piping systems, which promises significant improvements in stability and performance.

DIN rubber expansion joints, known for their compliance with stringent German standards (DIN), offer unparalleled flexibility and reliability. These joints are integral in large-scale grain storage facilities like the Central Reserve Grain Nest Lake Direct Subsidiary Warehouse, providing multiple advantages that enhance operational effectiveness and safeguard the infrastructure.

One of the foremost applications of DIN rubber expansion joints within the warehouse is the compensation for thermal expansion and contraction. The facility’s piping systems are subjected to considerable thermal stress due to seasonal temperature variations. DIN rubber expansion joints adeptly absorb these thermal fluctuations, preventing undue stress on pipelines and reducing the likelihood of structural damage and leaks. This capability ensures the integrity of the warehouse’s infrastructure, thus protecting the stored grain from potential contamination or spoilage.

In addition, DIN rubber expansion joints significantly reduce vibrations and oscillations within the warehouse. These vibrations can stem from the operation of heavy machinery and other dynamic activities within the facility. By effectively absorbing and mitigating these vibrations, DIN rubber expansion joints help preserve the stability and longevity of the piping systems and associated equipment, ensuring smooth and uninterrupted operations.

Furthermore, DIN rubber expansion joints are instrumental in accommodating pipeline misalignments and deformations due to ground settlement or seismic activity. Their flexible nature allows them to adjust to these structural shifts seamlessly, maintaining secure and stable connections. This adaptability not only enhances the safety of the warehouse but also minimizes the need for frequent maintenance and repairs, thus optimizing operational efficiency and reducing costs.

The decision to implement DIN rubber expansion joints within the Central Reserve Grain Nest Lake Direct Subsidiary Warehouse aligns with the facility’s commitment to operational excellence and innovation. This commitment is reflected in the warehouse’s numerous accolades, including being recognized as an “Advanced Direct Subsidiary Warehouse” and receiving multiple awards for operational efficiency and safety standards from both regional and national authorities.

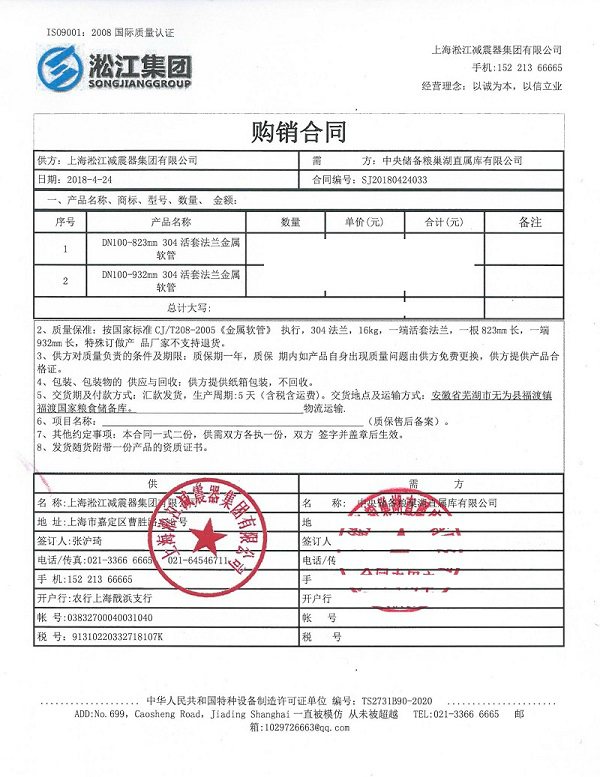

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the integration of DIN rubber expansion joints within the Central Reserve Grain Nest Lake Direct Subsidiary Warehouse represents a strategic initiative to enhance the facility’s operational efficiency, structural integrity, and safety. By effectively managing thermal fluctuations, dampening vibrations, and accommodating structural shifts, these expansion joints bolster the resilience and reliability of the warehouse’s infrastructure. This enhancement ensures that the warehouse continues to fulfill its critical role in grain storage and distribution with unparalleled efficiency and security.

Related links:304/316 flange Rubber expansion joint PN10 PN16 PN25

![[Air conditioning hose] metal hose of central air conditioning fan “Make every room quiet”](http://din-rubber-expansion-joint.com/wp-content/uploads/2022/05/Air-conditioning-hose-flexible-connection-1.jpg)

![[Exhibition hall] Take you to experience the rubber expansion joint Pn6 Pn10 Pn16 Pn25 exhibition hall](http://din-rubber-expansion-joint.com/wp-content/uploads/2022/06/Exhibition-hall-Take-you-to-experience-the-rubber-expansion-joint-Pn6-Pn10-Pn16-Pn25-exhibition-hall-1.jpg)