In the realm of automotive innovation, Tesla shines as a beacon of progress and sustainability. Renowned for its groundbreaking electric vehicles and visionary approach to manufacturing, Tesla continuously sets new standards in the industry. The Shanghai Tesla Gigafactory, situated in the heart of Shanghai’s industrial hub, stands as a testament to Tesla’s commitment to excellence and efficiency. Amidst its myriad achievements, the recent integration of Songjiang metal hoses, produced by Shanghai Songjiang Vibration Absorber Co., Ltd.which specializes in manufacturing din rubber expansion joints and spring vibration isolators, underscores Tesla’s dedication to innovation and reliability.

Since its establishment, Shanghai Tesla Gigafactory has been a symbol of technological prowess and sustainable manufacturing practices. With an annual production capacity of 250,000 electric vehicles, including the highly acclaimed Model 3 series, the Gigafactory exemplifies Tesla’s relentless pursuit of excellence. Its strategic localization efforts and meticulous attention to detail reflect Tesla’s commitment to delivering high-quality products while minimizing environmental impact.

Embedded within the intricate machinery of Shanghai Tesla Gigafactory, Songjiang metal hoses play a crucial role in ensuring the seamless operation of critical systems. Engineered to withstand extreme pressures and temperatures, these hoses serve as integral components in hydraulic circuits and cooling systems, ensuring the reliability and performance of Tesla vehicles. Their flexibility and durability not only optimize production efficiency but also contribute to the longevity and sustainability of EV manufacturing processes.

The integration of Songjiang metal hoses into Shanghai Tesla Gigafactory exemplifies the synergy between innovation and reliability. By partnering with Shanghai Songjiang Vibration Absorber Co., Ltd., Tesla reinforces its commitment to sourcing high-quality components locally while maintaining global standards of excellence. Moreover, the reliability and performance of Songjiang metal hoses enhance the overall efficiency of production processes, enabling Tesla to deliver premium electric vehicles that exceed customer expectations.

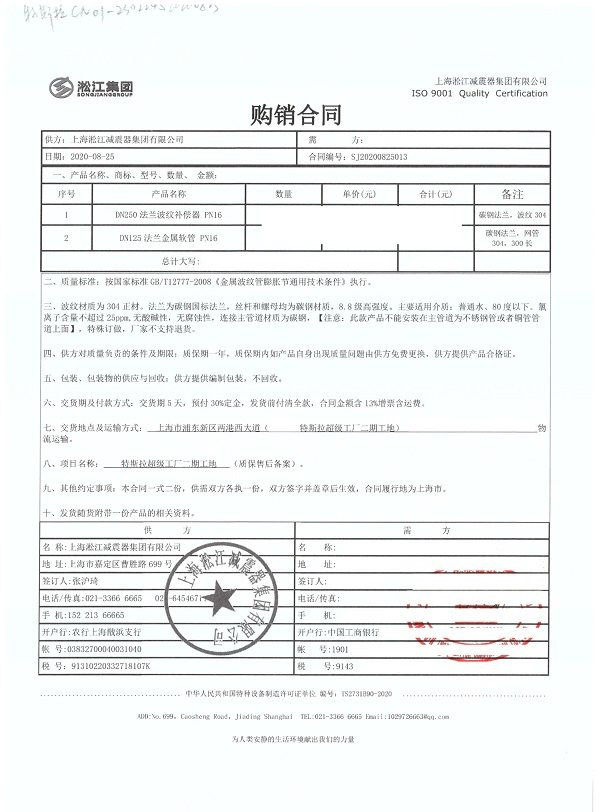

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the incorporation of Songjiang metal hoses at Shanghai Tesla Gigafactory represents a significant step forward in the pursuit of manufacturing excellence. As Tesla continues to push boundaries and redefine industry norms, the partnership with Songjiang reflects its dedication to advancing innovation and driving positive change. Together, they pave the way for a future where excellence and sustainability converge, shaping the automotive landscape for generations to come.

Related links:TW type stainless steel metal Expansion Joint “Food, MedicineJ and Chemical Industry”