Amidst the bustling hub of automotive engine production, Geely Powertrain Yiwu Factory(the collaborative partner of the Shanghai Shanghai Songjiang Group which specializes in manufacturing din rubber expansion joints and spring vibration isolators ) stands as a beacon of innovation and efficiency. Nestled within the vibrant Nanqingkou Automobile Industry Park in Zhejiang Province, China, this cutting-edge facility houses the Machining Fluid Workshop—a pivotal space where precision machining harmonizes with fluid dynamics.

Introduction to Geely Powertrain Yiwu Factory:

Geely Powertrain Yiwu Factory represents a pinnacle of technological advancement within the automotive industry. Comprising Zhejiang Fengrui Engine Co., Ltd., Zhejiang Yili Auto Parts Co., Ltd., and Yiwu Geely Engine Co., Ltd., this facility is dedicated to the research, development, manufacturing, and service of automotive engines.

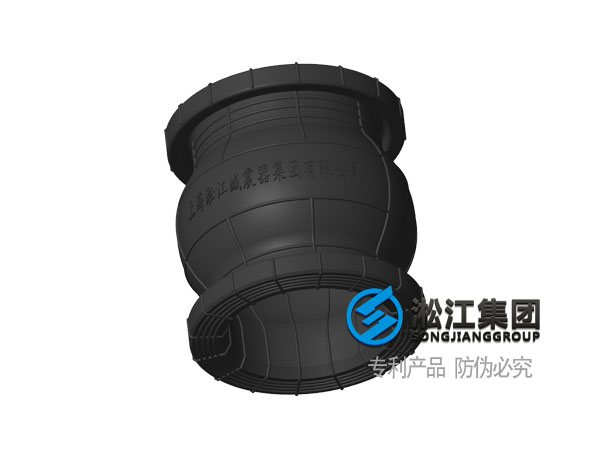

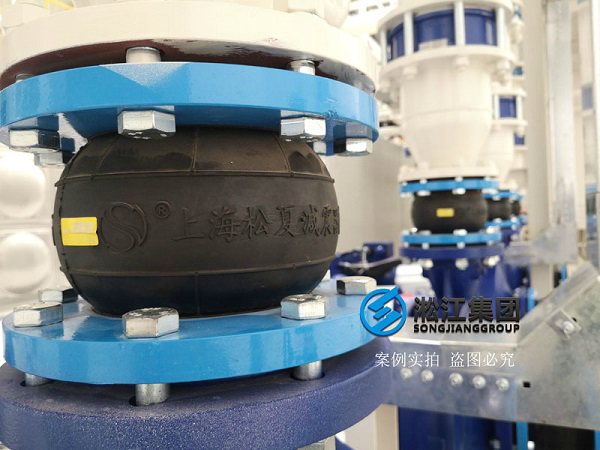

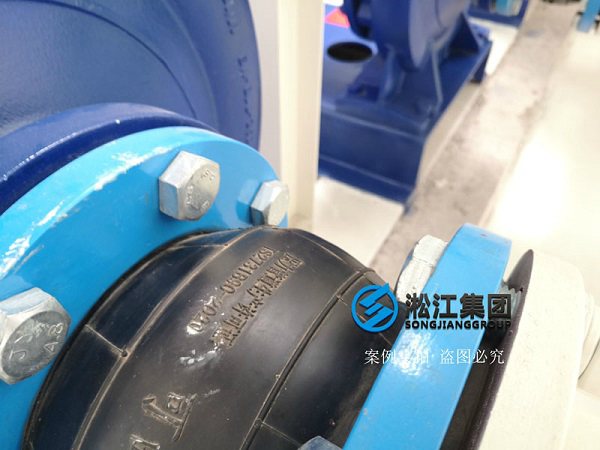

The Role of DIN Rubber Expansion Joints:

Within the fluid-intensive environment of the Machining Fluid Workshop, DIN rubber expansion joints play a vital role. These components, renowned for their reliability and durability, serve multiple critical functions:

Corrosion Resistance: DIN rubber expansion joints are designed to withstand exposure to corrosive fluids commonly found in machining environments, ensuring longevity and reliability.

Temperature Resistance: Operating within environments subject to fluctuating temperatures, DIN rubber expansion joints exhibit resilience against heat, preserving structural integrity and performance.

Pressure Resistance: Machining processes often generate significant fluid pressures, necessitating DIN rubber expansion joints capable of withstanding these forces without compromising safety or functionality.

Flexibility: DIN rubber expansion joints offer exceptional flexibility, accommodating dynamic movements and vibrations inherent in machining operations, thereby enhancing operational efficiency.

Sealing Performance: Effective sealing properties are essential to prevent fluid leaks, ensuring a clean and safe working environment while reducing downtime.

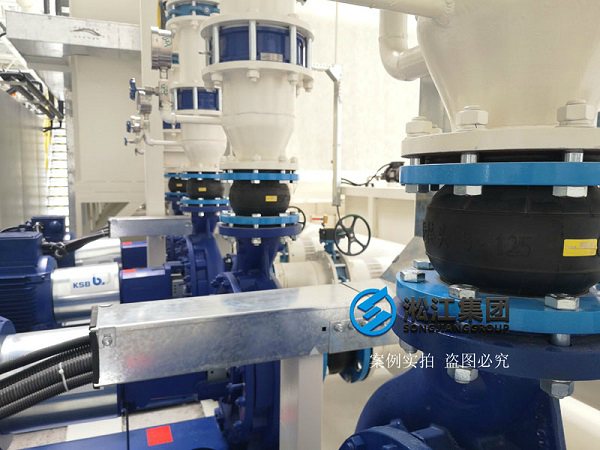

Integration of DIN Rubber Expansion Joints:

Recognized for their superior quality and reliability, DIN rubber expansion joints provided by Shanghai Songjiang Vibration Absorber Co., Ltd. are seamlessly integrated into the Machining Fluid Workshop at Geely Powertrain Yiwu Factory. These components optimize operations, enhance equipment longevity, and ensure a safe working environment.

Benefits and Outcomes:

By incorporating DIN rubber expansion joints, Geely Powertrain Yiwu Factory elevates operational efficiency, mitigates downtime, and ensures equipment longevity. With exceptional corrosion resistance, temperature tolerance, flexibility, and sealing capabilities, these joints contribute to a safer, cleaner, and more productive working environment.

Conclusion:

In the dynamic realm of automotive engine production, Geely Powertrain Yiwu Factory continues to set benchmarks for quality, reliability, and performance. Through the strategic integration of DIN rubber expansion joints within its Machining Fluid Workshop, the facility advances innovation, driving the automotive industry towards a sustainable future.

Related links:Appearance Patent DN150 KXT Rubber expansion joint PN10 PN16 PN25 with Flanges For fire pipes