As a company specializing in industrial vibration control and pipeline connection solutions, Shanghai Songjiang Group has been devoted to developing and producing high-quality din rubber expansion joints for global industries. With advanced technology and extensive experience, Songjiang Group has become a trusted partner in the industrial field. For large-scale and technologically advanced projects like the Thailand Mitsui KSP sugar mill, selecting high-quality equipment and accessories is crucial. In this regard, the DIN rubber expansion joints produced by Shanghai Songjiang Group have demonstrated outstanding performance and reliability, successfully applied in this project.

The advantages of DIN rubber expansion joints are noteworthy:

Excellent Wear Resistance: DIN rubber expansion joints utilize high-quality EPDM rubber material, meticulously designed for exceptional wear resistance. This is particularly vital for equipment frequently used in industrial environments like sugar mills, effectively prolonging lifespan and reducing maintenance costs.

Secure Connections: Equipped with flanges treated with hot-dip galvanization, DIN rubber expansion joints ensure robust connections resistant to corrosion. In large-scale projects like the Thailand Mitsui KSP sugar mill, secure pipeline connections are paramount, and DIN rubber expansion joints provide reliable solutions.

Superior Weather Resistance: EPDM rubber material boasts excellent weather resistance and aging resistance, adapting to various climate conditions and environmental changes. This enables the rubber expansion joints to operate stably in Thailand’s hot and humid climate, providing reliable support for the sugar mill’s continuous production.

High-Strength Tie Rods: DIN rubber expansion joints feature tie rods made of high-strength carbon steel, ensuring structural stability and durability of the equipment. This is particularly crucial for pipeline systems handling high-pressure and high-temperature fluids, effectively absorbing vibrations and coping with thermal expansion and contraction.

In the Thailand Mitsui KSP sugar mill project, Songjiang DIN rubber expansion joints have been successfully applied in various critical equipment and pipeline connections. Across different production stages of the sugar mill, where a large number of equipment and pipeline connections are involved, Songjiang DIN rubber expansion joints have provided reliable connection solutions, ensuring the stable operation of the production system. Especially in high-temperature and high-pressure connections of thermal processing equipment, the exceptional performance of these joints has made them an ideal choice. Furthermore, in the long-term operation of pipeline systems, issues such as vibration and thermal expansion and contraction may affect connection components. However, the high-strength tie rod design of Songjiang DIN rubber expansion joints effectively mitigates these issues, ensuring the stability of the pipeline system.

Related links:304/316 flange Rubber expansion joint PN10 PN16 PN25

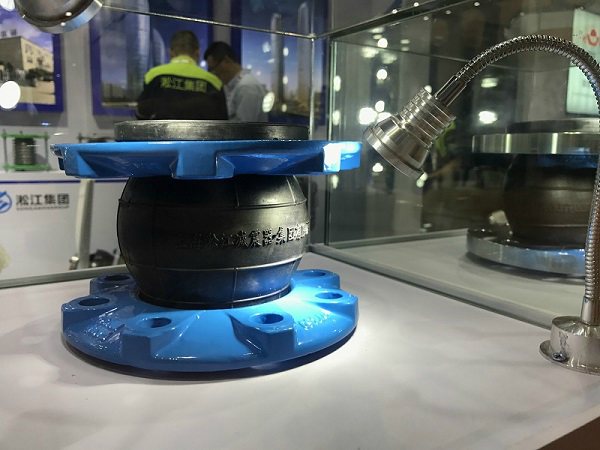

![[Exhibition hall] Take you to experience the rubber expansion joint Pn6 Pn10 Pn16 Pn25 exhibition hall](http://din-rubber-expansion-joint.com/wp-content/uploads/2022/06/Exhibition-hall-Take-you-to-experience-the-rubber-expansion-joint-Pn6-Pn10-Pn16-Pn25-exhibition-hall-1.jpg)