In the context of the power plant retrofit project at the Long Gu Tan power plant, which is under the banner of Veolia and the CLP Group, Songjiang din rubber expansion joints have proven to be a vital component. These Din rubber expansion joints offer exceptional characteristics that make them the preferred choice for large-scale factory wastewater treatment systems.

Corrosion Resistance: The wastewater and sewage in large industrial facilities often contain various corrosive chemicals. Therefore, rubber expansion joints need to exhibit outstanding corrosion resistance. This necessitates the selection of rubber materials like EPDM and Viton to withstand chemical corrosion and the effects of acidic or alkaline substances.

High-Temperature and Low-Temperature Performance: Wastewater treatment systems may operate in extreme temperature conditions, be it high or low. Consequently, the rubber materials used in expansion joints must have the ability to endure these temperature extremes without becoming rigid or brittle.

High Strength and Pressure Resistance: Wastewater treatment systems typically deal with substantial water flow and pressure. As a result, rubber expansion joints must possess sufficient strength and pressure resistance to prevent leakage or rupture.

Excellent Flexibility and Bendability: Rubber expansion joints should be capable of accommodating the flexing and deformation within the system to adapt to pipeline vibrations and changes. This necessitates the expansion joints to have excellent flexibility to avoid stress concentration and potential ruptures.

Wear Resistance: When dealing with a significant volume of wastewater, the encountered water may contain particulate matter, leading to wear. Hence, rubber expansion joints must be wear-resistant to extend their lifespan.

Ease of Installation and Maintenance: Large industrial facilities require regular maintenance and servicing of wastewater treatment systems. Therefore, the design of rubber expansion joints should consider easy installation and maintenance to reduce downtime and maintenance costs.

Compliance with Regulations and Standards: Rubber expansion joints must comply with local and international regulations and standards to ensure safety and reliability. This includes adherence to relevant standards related to materials, performance, and durability. Wastewater treatment and sewage discharge systems are typically subject to regulatory oversight. Therefore, rubber expansion joints must conform to applicable regulations and standards to ensure compliance.

The following physical photo is a detailed introduction about Songjiang din rubber expansion joint

The following physical photo is a detailed introduction about Songjiang din rubber expansion joint

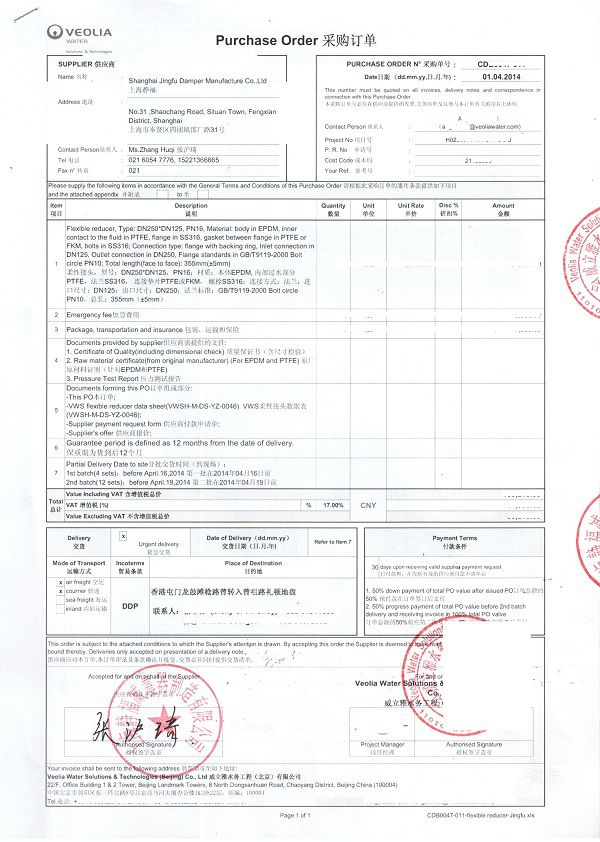

The following agreement is a detailed introduction about the din rubber expansion joint for Long Gu Tan power plant

The following agreement is a detailed introduction about the din rubber expansion joint for Long Gu Tan power plant

In conclusion, Songjiang din rubber expansion joints offered by Shanghai Songjiang Shock Absorber Group have proven to meet these essential requirements and are a reliable choice for the Long Gu Tan power plant retrofit project. Their exceptional attributes ensure they can handle the demanding conditions of large-scale wastewater treatment systems.

Related links:[EPDM] with tie rod Rubber expansion joint PN16 “enhanced”